3D printing is based on the concept of constructing an object in sequential layers that represent the contours of the model. We describe what materials are used in 3D printing.

If you are interested in the characteristics of materials, then visit this page.

General description of materials

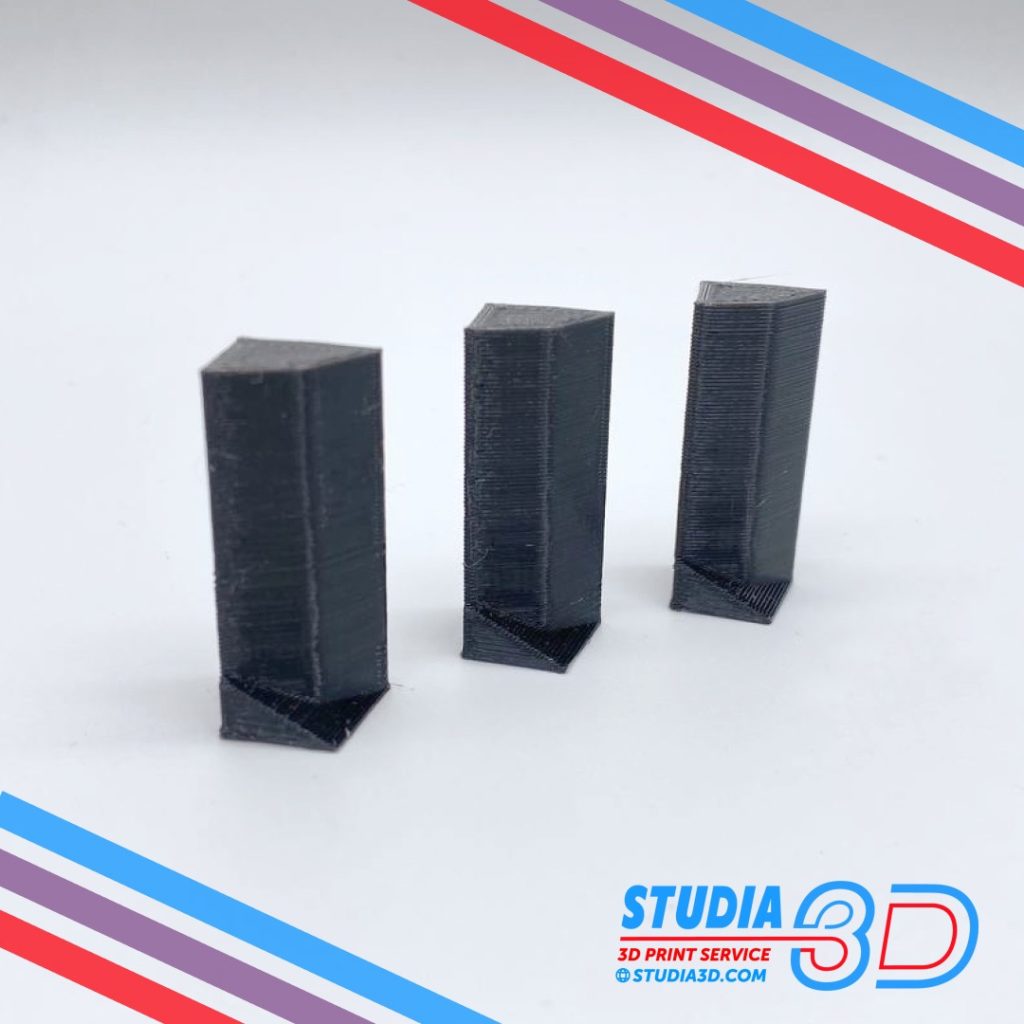

The most common 3D printing method is extrusion (FDM). Standard parameters for FDM 3D printing: layer height - 0.2 mm, nozzle diameter - 0.4 mm, wall thickness, top and bottom floors - 1.2 mm. Below are the main materials used in this printing method:

● Polyethylene terephthalate glycol (PET-G, PETG)

This material is by default in the automatic costing system. In 90% of cases, customers choose this material. We also recommend it most often. This material solves most problems and has an excellent price-quality ratio. The material combines the positive features of such materials as: ABS (high strength), PLA (excellent accuracy and shrinkage). The material has high chemical resistance to acids, alkalis and organic solvents. Possesses high wear resistance. Among other things, the material is relatively easy to machine.

PET-G V0 is an innovative material developed by our company specifically for 3D printing. Its main advantage is its non-flammable properties, making it an ideal choice for projects where safety is key. This material ensures the reliability and safety of your printed products. Our research and development is focused on creating the highest quality materials, and PET-G V0 is a prime example of this philosophy. You can trust its reliability and use it in a wide range of applications, be it prototyping or manufacturing functional parts.

● Polylactide (PLA, PLA)

PLA is an environmentally friendly, biodegradable material made from corn and sugar cane. Plastic absorbs moisture well and is not suitable for functional use (an exception is an unloaded plain bearing, since PLA has a high slip coefficient). It is used for the manufacture of designer models, souvenirs and toys. It is widely used in 3D printing of prototypes, because it has the highest accuracy among materials in FDM technology. Great for making mockups as it is non-toxic and accurate.

● WAX (WAX, WAX)

Recently we started using WAX in FDM printing. An excellent solution for burnt products. The best solution for foundries when it comes to large items. No shrinkage, which indicates good accuracy of products.

● WAX Resin (WAX, WAX)

Castable Wax Resin is an outstanding material developed specifically for the production of precision casting models. Using SLA technology, this material provides incredibly high detail and precision, making it an ideal choice for jewelry, dentures and other applications where a flawless surface and guaranteed dimensions are required. Castable Wax Resin has excellent compressibility, which facilitates the casting process and the production of high-precision parts. Create jewelry and prototypes with Castable Wax Resin for outstanding results.

● VisiJet M2 CAST Resin (WAX, WAX)

VisiJet M2 CAST Resin is an innovative material developed for use in 3D printing systems using MultiJet Printing (MJP) technology. This material is ideal for creating models and molds intended for further casting. Its high precision and reliability guarantee high-quality casting without loss of parts and dimensions. VisiJet M2 CAST Resin has excellent thermal characteristics, which allows you to produce cast products with minimal deformation. This material is suitable for a wide range of applications including jewelry manufacturing, medical modeling and prototyping. With VisiJet M2 CAST Resin you can be confident in the high quality and precision of your castings.

● Acrylonitrile Butadiene Styrene (ABS, ABS)

ABS is widely used in industry: the production of car parts, cases of various devices, containers, souvenirs, various household accessories, etc. ABS-plastic is resistant to moisture, acids and oil, has a fairly high thermal resistance - from 90 ° C to 110 ° C ... Unfortunately, some types of material deteriorate when exposed to direct sunlight, which somewhat restricts their application, however, plastic is easy to paint and a protective coating can be applied to the finished product. It has a large shrinkage, therefore it is printed only in a closed chamber.

● Acrylonitrile butadiene styrene M30 (ABS, ABS)

ABS M30 Plastic is a high quality material that is perfect for professional 3D printing. This plastic is known for its outstanding strength and resistance to various factors, including mechanical stress and temperature changes.

ABS M30 Plastic is ideal for creating functional prototypes, engineering parts and even final products. Its high strength makes it an excellent choice for projects that require durability and resistance.

This material also lends itself well to finishing, allowing you to further finish and modify your parts. Thanks to its low cooling shrinkage rate, ABS M30 Plastic provides high part fidelity.

ABS M30 Plastic is used in a wide range of industries such as industrial manufacturing, automotive, medical equipment and many others. This material is proven to be reliable and effective for your 3D projects.

● Styrene-butadiene copolymer (SBS, SBS)

SBS (Styrene Butadiene Copolymer) is a high quality 3D modeling material, great for 3D pen creativity and design. SBS has an amazing combination of properties: a high level of hardness and high elasticity, which is retained even at low temperatures. The absence of shrinkage allows printing large-sized models, while the models retain their elasticity - they are difficult to break or split. Unique dyeing formulations allow to obtain models with bright, crystal clear colors. Easy processing of finished models (solvent or D-limonene) unsurpassed gloss and transparency make SBS an indispensable material for striking design solutions.

● Acrylonitrile (ASA, ACA)

The material is highly durable and resistant to external factors. It is also UV resistant and practically unaffected by lubricants, dilute acids and diesel fuel. Compared to ABS plastic, it is resistant to ultraviolet radiation, has increased adhesion and a noticeably less heat shrinkage effect. The material is perfect for printing cases of outdoor devices, street lighting equipment, elements of cars, marine and aerial equipment (both external and internal elements) and items that are exposed to the environment during operation.

● CERAMO (KERAMO)

A unique material that imitates ceramic products. It has no analogues in the market of consumables for 3D printing. Tough, durable with excellent adhesion between layers. Ready-made prints are practically indistinguishable from faience and ceramics in terms of their tactile properties. Hard, pleasant to the touch, cool, heavy and sonorous on impact. The material lends itself perfectly to abrasive materials, emery papers and can even be mechanically polished with fine abrasive finishing emery papers. Wet sanding is recommended. Heat resistance of the material, exceeding the boiling point of water (up to 102 ° C), makes it possible to use it for printing unique tableware (for example, souvenir cups). All polymers and fillers used in the production of CERAMO are food grade and are suitable for contact with hot food.

● Nylon (nylon)

Nylon is an artificial thermoplastic polymer, also called polyamide. The characteristics are similar to ABS plastic. Nylon has high wear resistance and low coefficient of friction. Therefore, it is often used to coat rubbing parts, which improves their performance and often allows them to function without lubrication. This type of plastic in the form of a filament (filament) is used in 3D printing using FDM technology, and in the form of a powder it can be used in SLS and other similar methods.

● Polypropylene (PP, PP)

Polypropylene, or PP, is a popular 3D printing material with low density, making it lightweight and easy to use. This plastic is highly chemical resistant and resistant to many chemicals, making it ideal for applications where resistance to harsh environments is required.

Polypropylene is also known for its resistance to high temperatures, allowing its products to be used in a variety of engineering and technical applications. It withstands mechanical loads well and has outstanding insulating properties.

This material is suitable for creating functional prototypes, cases and parts, as well as for the production of containers and containers, including food containers. Polypropylene can be used in many industries, including automotive, medical equipment, and consumer electronics, where its lightness and strength are useful.

Combining lightness, durability and chemical resistance, PP is a great material for your next 3D project.

● Thermoplastic polyurethane (TPU, TPU)

Thermoplastic polyurethane. The most resilient and durable material in the flexible plastics range. Differs in high chemical resistance to oils, gasolines, alkalis and some acids. Possesses high strength in bending and tensile deformation. In addition, the polymer has good resistance to seawater, grease, and is not susceptible to germs or bacteria. The material has a high level of resistance to natural aging and is recyclable.

● Composite (TPU GF, TPU CF)

Thermoplastic polymer, on high-grade carbon or glass fibers. In terms of its characteristics, it surpasses ABS, PLA and SBS in terms of: non-carcinogenic, ultra-strong, matte surface, insoluble in solvents, does not absorb moisture, soft - better amenable to mechanical post-processing, better tolerates environmental conditions. It can be used as the main material of the product.

| ID28 ABS GF-12 Composite ABS with 12% chopped glass fiber content Technology: FDM 3D printing |

ID29 ABS/PA 6 GF-8 Composite A mixture of ABS and PA6 with the addition of 8% fiberglass Technology: FDM 3D printing |

| ID30 PP GF-30 Composite Polypropylene with 30% glass fiber content Technology: FDM 3D printing |

ID31 PA66 GF-30 Composite Polyamide with 30% glass fiber content Technology: FDM 3D printing |

| ID32 TPU GF-30 Composite Impact resistant 30% TPU composite Technology: FDM 3D printing |

ID33 TPU GF-10 Composite Impact resistant 10% TPU composite Technology: FDM 3D printing |

| ID34 ABS GF-4 Composite ABS reinforced with 4% chopped fiberglass Technology: FDM 3D printing |

ID39 Gypsum Composite Gypsum composite for color 3D printing Technology: CJP 3D printing |

Composite materials for 3D printing are a variety of combinations of plastics and glass fibers, providing an expanded range of characteristics and capabilities. Regardless of the specific composition, they combine several key features:

- Strength and Durability: Composite materials have increased strength and the ability to withstand mechanical loads. This makes them an ideal choice for creating durable and reliable parts.

- Temperature Resistance: Many are designed to operate in extreme temperature conditions, allowing them to be used in a variety of applications.

- Chemical Resistance: Some composites are resistant to harsh chemicals, making them suitable for laboratory and industrial applications.

- Flexibility and Shock Absorption: Some TPU-based composites provide flexibility and shock absorption, which is useful in creating shock-absorbing and damping components.

- Advanced 3D Printing Capabilities: Composites are designed with 3D printing technology in mind, allowing the creation of complex geometric shapes and parts.

- Variety of Applications: Their versatility and variety of characteristics make composite materials suitable for a variety of industries, including aviation, medical, automotive, and more.

Composites have become an important part of 3D printing, giving engineers and designers more freedom and opportunity to create innovative products and prototypes.

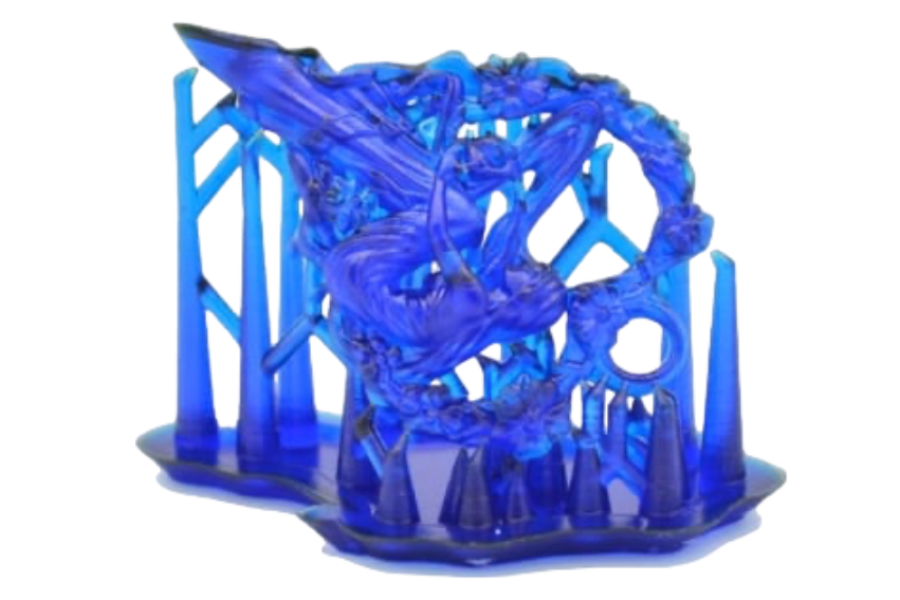

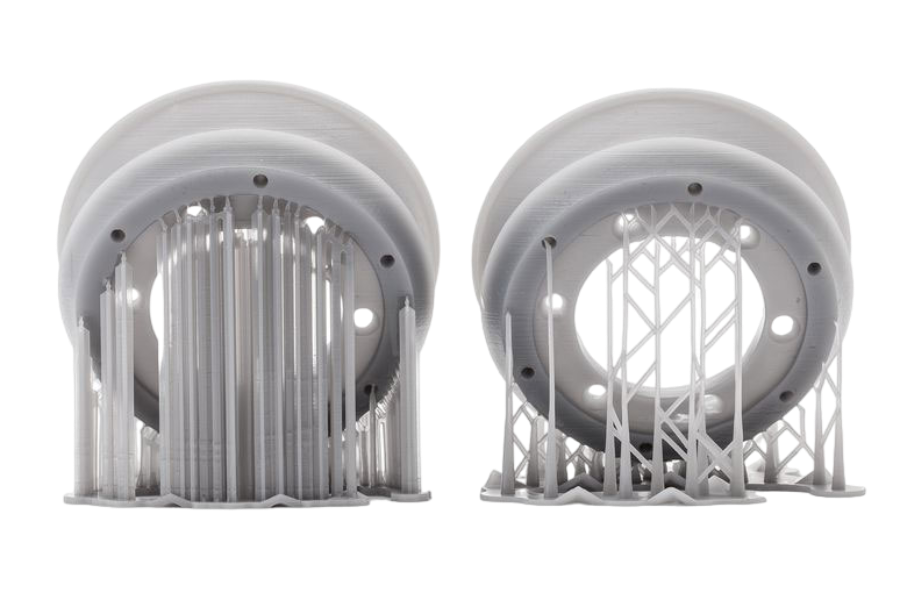

● Photopolymer (SLA/LCD/DLP)

A substance that changes its properties under the influence of light, more often ultraviolet light. Mainly soft and light-sensitive material before exposure to light. The photopolymer is used in dental prosthetics for Infill forms, in the manufacture of printing plates for stamps (seals), microcircuits and printed circuit boards, and in other fields. The highest manufacturing precision. The difference is that SLA technology has treelike supporting structures, while MJP technology is paraffinic. The SLA has a layer height of 50 micrometers, while the MJP has 32 micrometers.

● Photopolymer ABS Like Resin (SLA/LCD/DLP)

ABS Like Resin is a material designed to create parts similar to those made from ABS plastic. It has high strength and impact resistance, making it an excellent choice for a variety of applications, including housing and functional parts.

These materials provide a variety of options for 3D printing and allow the creation of parts with varying degrees of strength, flexibility and detail depending on the specific requirements of the project.

● Photopolymer ABS Tough Resin (SLA/LCD/DLP)

ABS Tough Resin is a durable 3D printing material that is highly impact and mechanical resistant. It is ideal for creating functional parts and prototypes that must withstand stress. This material also has good chemical resistance.

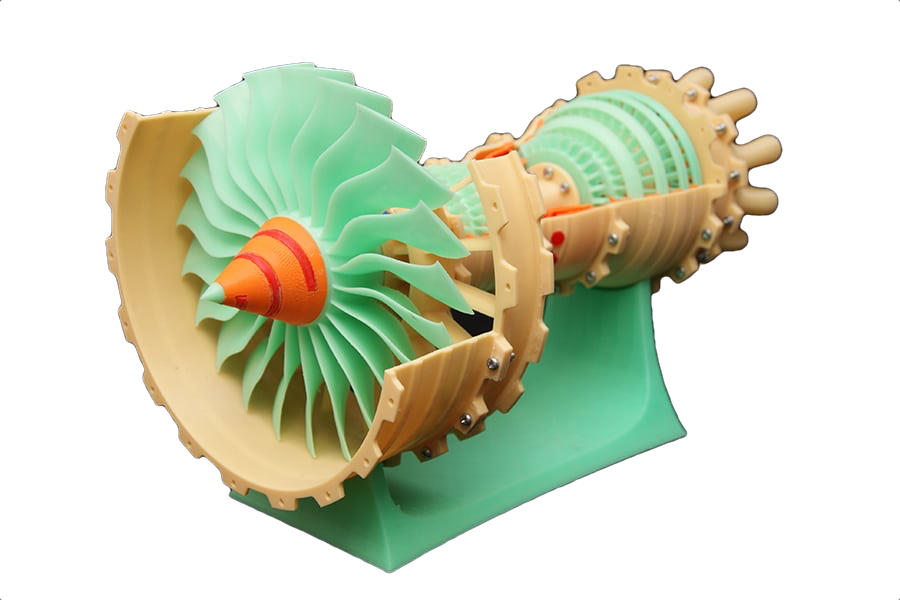

Light polymer VisiJet Resin (MJP)

VisiJet Resin is a high quality 3D printing material that provides excellent detail and precision. This material is suitable for a wide range of applications including prototyping, concept models and functional parts. Its high quality surface makes it ideal for creating parts with complex geometries.

Light polymer MIMAKI Resin (MJP)

MIMAKI Resin is a high-quality SLA (photosensitive resin) 3D printing material that provides high precision and detailed parts. It is great for creating prototypes and concept models, as well as for producing jewelry and other parts that require high detail.

● Polyamide (SLS)

Structural polymer material with good strength and antifriction properties. This polyamide is chemically resistant to oils, gasoline, alcohol, weak acids, diluted and concentrated alkalis, and is non-toxic. Layer height 0,1 mm. The minimum wall thickness is 1 mm.

● TPU Flexa Black (SLS)

TPU (thermoplastic polyurethane) Flexa Black is a flexible 3D printing material that combines elasticity and strength. It is ideal for creating parts that require flexibility and resistance to bending and stretching. This material also has good wear resistance.

● Metal 316L Stainless Steel (SLM)

316L stainless steel is a metal material that is widely used in 3D printing due to its high strength and ability to maintain integrity in harsh environments. This material is ideal for creating parts that are subject to mechanical stress and corrosion.

● Metal AlSi10Mg Aluminum (SLM)

AlSi10Mg, an aluminum alloy, is a popular material for metal 3D printing due to its lightness and strength. This alloy is composed of aluminum (Al), silicon (Si) and magnesium (Mg), making it an excellent choice for a wide range of applications.

The main advantage of AlSi10Mg is its low density, which makes it one of the lightest metal materials used in 3D printing. At the same time, it has outstanding strength and resistance to mechanical stress, which allows you to create parts that can withstand significant loads.

AlSi10Mg has high thermal stability, making it suitable for applications requiring high temperature resistance. The material also lends itself well to processing and finishing, making it ideal for creating complex parts and components.

Due to its strength, lightness and high stability, AlSi10Mg aluminum is popular in aviation, automotive, aerospace and other applications where lightweight and strong metal parts are required.

Material classifier

| ID | Name | Description | Technology |

| ID1 | PLA Plastic | Polylactide is biodegradable and biocompatible | FDM 3D printing |

| ID2 | PA1200 Polyamide | Powder material based on polyamide 6 | SLS 3D printing |

| ID3 | PET-G Plastic | Polyethylene terephthalate glycol (PET-G) - plastic | FDM 3D printing |

| ID4 | ABS Plastic | Acrylonitrile butadiene styrene thermoplastic | FDM 3D printing |

| ID5 | ASA Plastic | Amorphous polymer with high impact strength | FDM 3D printing |

| ID6 | SBS plastic | Styrene-butadiene-styrene rubber moisture-resistant | FDM 3D printing |

| ID7 | Nylon Filament | The most heat-resistant wear-resistant plastic | FDM 3D printing |

| ID8 | CERAMO Plastic | Easy to grind and polish | FDM 3D printing |

| ID9 | TPU CF-5 Composite | Impact resistant carbon-filled (5%) plastic | FDM 3D printing |

| ID10 | TPU FLEX Filament | The most elastic and wear-resistant material | FDM 3D printing |

| ID11 | VisiJet Resin | Elastomeric material for high precision | MJP 3D printing |

| ID12 | Basic Resin | Monomers hardening under the influence of UV | SLA 3D printing |

| ID13 | TPU Flexa Black | Powder based on polyurethane elastomer | SLS 3D printing |

| ID14 | MIMAKI Resin | Elastomeric material for high precision | MJP 3D printing |

| ID15 | PA2200 Polyamide | Powder material based on polyamide 12 | SLS 3D printing |

| ID16 | Wax Filament | Lost wax for FDM technology | SLS 3D printing |

| ID17 | AlSi10Mg Aluminum | Curable aluminum alloy | SLM 3D printing |

| ID18 | 316L Stainless steel | Features increased corrosion resistance | SLM 3D printing |

| ID19 | ABS M30 Plastic | Industrial thermoplastic for 3D printing | FDM 3D printing |

| ID20 | PA 3200 GF Polyamide | PA composite - has high rigidity | SLS 3D printing |

| ID21 | VisiJet M2 CAST Resin | More durable and at the same time flexible wax | MJP 3D printing |

| ID22 | WAX Resin | Lost wax for SLA technology | SLA 3D printing |

| ID28 | ABS GF-12 Composite | ABS with 12% chopped glass fiber content | FDM 3D printing |

| ID29 | ABS/PA 6 GF-8 Composite | A mixture of ABS and PA6 with the addition of 8% fiberglass | FDM 3D printing |

| ID30 | PP GF-30 Composite | Polypropylene with 30% glass fiber content | FDM 3D printing |

| ID31 | PA66 GF-30 Composite | Polyamide with 30% glass fiber content | FDM 3D printing |

| ID32 | TPU GF-30 Composite | Impact resistant 30% TPU composite | FDM 3D printing |

| ID33 | TPU GF-10 Composite | Impact resistant 10% TPU composite | FDM 3D printing |

| ID34 | ABS GF-4 Composite | ABS reinforced with 4% chopped fiberglass | FDM 3D printing |

| ID35 | ABS Tough Resin | rigidity, flexibility and tensile strength | SLA 3D printing |

| ID37 | PET-G V0 Plastic | PET-G with Nonflammables | FDM 3D printing |

| ID38 | PP Filament | Plastic filament impact resistant | FDM 3D printing |

| ID39 | Gypsum Composite | Gypsum composite for color 3D printing | CJP 3D printing |

| ID41 | ABS Like Resin | UV monomer with properties of ABS plastic | SLA 3D printing |

Color classifier

| ID | Name | A type | Value |

| ID2 | Transparent | Transparent | ◉ |

| ID7 | Milky | Opaque | ◉ |

| ID8 | White | Opaque | ◉ |

| ID9 | Black | Opaque | ◉ |

| ID10 | Red | Opaque | ◉ |

| ID11 | Blue | Opaque | ◉ |

| ID12 | Yellow | Opaque | ◉ |

| ID13 | Turquoise | Opaque | ◉ |

| ID14 | pale blue | Opaque | ◉ |

| ID15 | Green | Opaque | ◉ |

| ID16 | Brown | Opaque | ◉ |

| ID17 | Orange | Opaque | ◉ |

| ID18 | Silvery | Opaque | ◉ |

| ID19 | Purple | Opaque | ◉ |

| ID21 | Gray | Opaque | ◉ |

| ID22 | Purple | Opaque | ◉ |

| ID23 | Green Transparent | Transparent | ◉ |

| ID24 | Beige | Opaque | ◉ |

If you have not found the material that suits you, you can check its availability, characteristics and printability with a specialist in Studia3D by phone +7 (495) 532-43-47 or email 3dprint@studia3d.com.com

Author: Studia3D. Ru

More articles from Studia3D. Ru