Imagine that you have a need for circulation of some products that are not produced in large quantities. Let's compare two technologies: injection molding and 3D truss.

Definitions.

Injection molding - Manufacturing of products by molding in metal molds using special machines called injection molding machines.

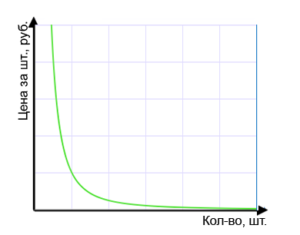

Formation of the price per unit of the product in the case of injection molding machines:

3D farm - a set of 3D printers, usually of the same type and performing standard tasks, within one enterprise. As a rule, it is a separate production center, although it can be included in an existing production.

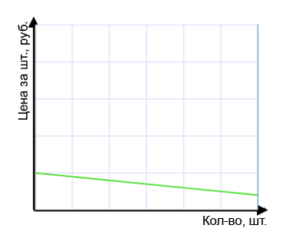

Formation of the price per unit of the product in the case of a 3D farm:

Why such difference? Because for casting on injection molding machines, it is necessary to make a mold, which itself sometimes costs several million rubles. The mold pays for itself only with thousands of copies (depending on the part, how more than 1000000 pieces were melted). In the case of 3D printing, it is important to work out only the control program, the so-called G-Code.

Economy.

We superimpose two graphs on top of each other.

Our market segment is immediately visible on the chart:

This zone can be up to 100 pieces of parts, and up to 100 pieces. It all depends not only on the complexity of the part, but also on the accuracy, purpose, load conditions and other factors, however, as experience shows, taking into account all factors, the picture will change little.

Technological complexities.

Everyone is accustomed to the fact that XNUMXD printing is expensive, slow and of poor quality.

Slow often refers to the slow growth rate of the model. But, if you have 100 units of 3D printers, it will take time for 100 items to grow. And you will notice that the growth rate is not that slow.

Expensive is usually the unit cost. Everything is very simple and depends on what to compare. With a disposable spoon that churns out millions of copies? No? Then try to cast 5 products in the injection molding machine. Once you know the cost of the mold, the desire to order will disappear. And what about 3D printing studios? As a rule, no more than 5-10 pieces of 3D printers, in the case of even mass orders, the studio cannot end up from the created stream of customers, but you cannot surpass yourself and you won’t start doing it for nothing, because you have to live on something even in the case of downloading one order for 3 months. The order that the studio makes in 3 months, the farm makes in 1-2 days. Therefore, the cost per unit of the product drops significantly.

And the last thing is accuracy. Accuracy, in my understanding, is an ambiguous thing. You cannot compare two products of the same shape, made, for example, on a milling machine and on a 3D printer. Each technology should have its own design cycle.

Project Studia3D.ru.

We believe in this technology, so we are announcing the first 3D farm in Russia. This has never happened on our land!

How many printers? By the end of 2020, we plan to launch 200 units of 3D printers. In addition to the 3D printing workshop, the 3D farm will include a model workshop, a painting chamber, a warehouse, a workshop for assembling and servicing 3D printers.

Author: Studia3D aggregator

More articles from Studia3D aggregator